Precision Stamping Mold - Terminal Mold

manufacturers: Foxdotec

Processing cycle: two weeks

Origin: China

Product introduction:

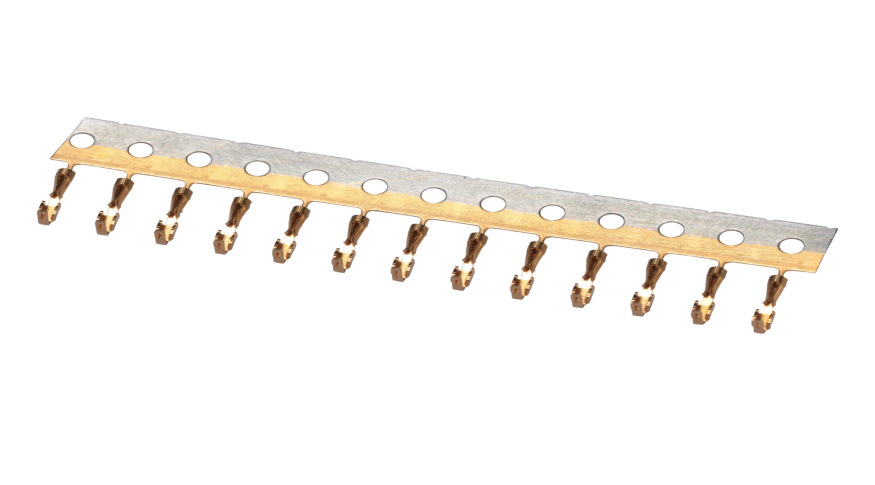

The terminal is a component of the battery connected to an external conductor. Electrical engineering, terminals multi-finger terminals, also known as terminals, types of single-hole, double-hole, socket, hooks, etc., from material division, copper silver plated, copper galvanized, copper, aluminum, iron and so on. Their role mainly transmits electrical signals or conductive uses. On the degree of mold precision, high-speed terminal mold here should be considered the most sophisticated.

Processing:

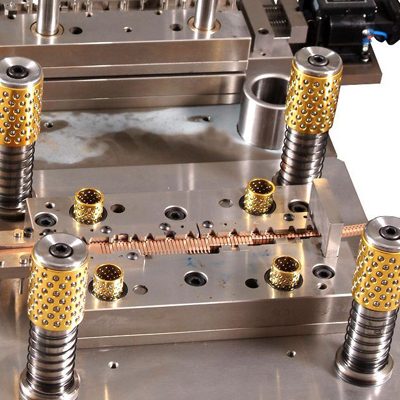

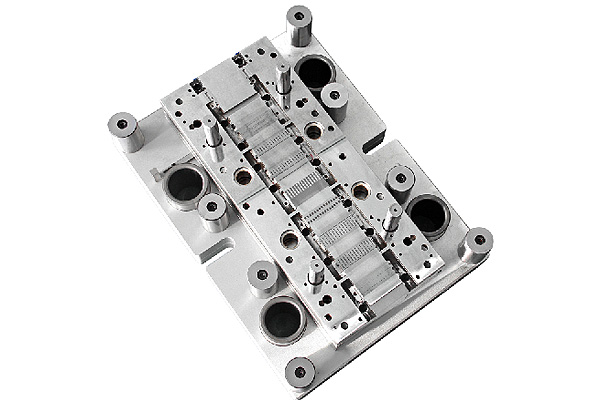

Terminal mold is divided into two and three die, terminal stamping mold structure for mold seat, pad plate (punch fixed plate, strip plate, knife fixed plate), punch column; Oil anti-rust according to the order, install external guide column, guide sleeve to use special positioning tools to ensure its verticality; template measured thickness, four-point measurement difference within 005mm for qualified; When repairing mold into the block accurate to 0.003mm, no precision concept, it is impossible to develop high-quality, it is not possible to install high-precision mold, mold design; mold processing; mold formation, test mold and repair. All three are indispensable. A set of high-precision molds to have a precise design, precision processing, but also have precision assembly.

Application range:

Precision connector terminals, medical terminals, automotive terminalmobile computer equipment, digital cameras, mobile communications equipment, automotive/aeronautical/navigational electronic components, medical electronics, smart home appliances, ICs, 3C products and outdoor waterproofing, etc.

Back To Home

Category: Stamping Die