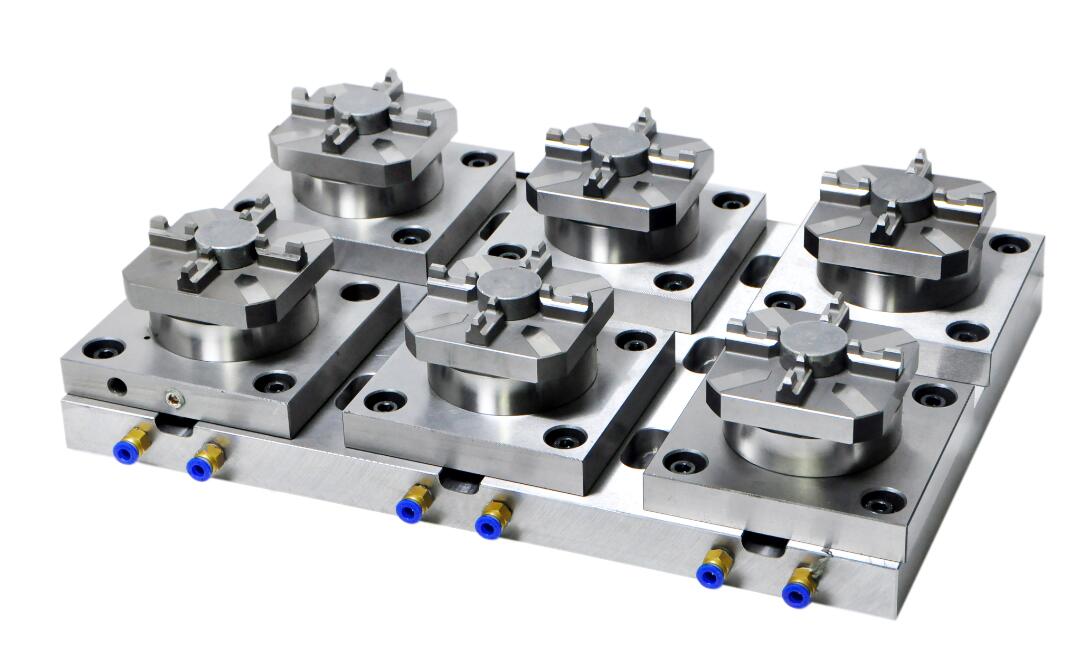

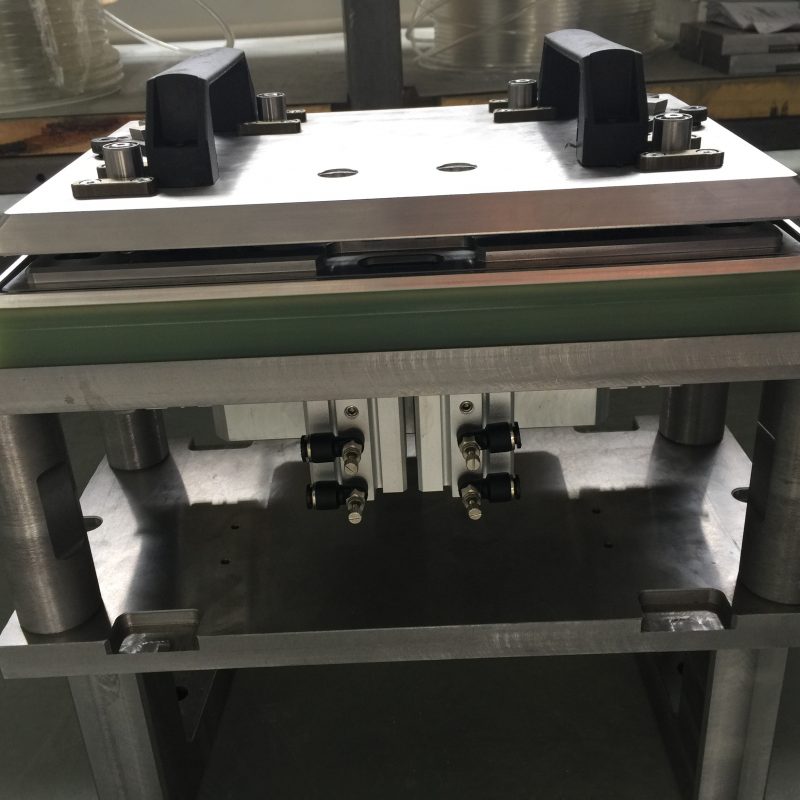

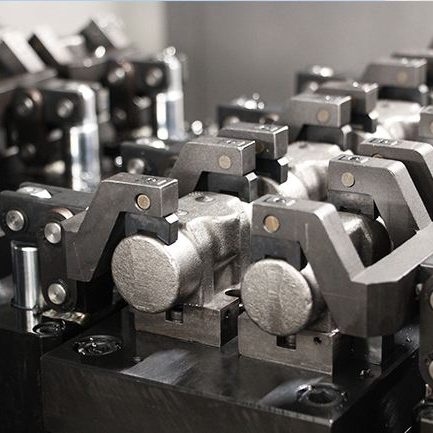

Jig & Fixture

Inspection is a simple tool for industrial production enterprises to control various sizes of products (e.g. aperture, space size, etc.) to improve production efficiency and quality, suitable for high-volume production of products, such as automotive components, replacing professional measuring instruments, such as smooth plug rules, thread plug rules, outer diameter card rules. Fixtures are devices used during the mechanical manufacturing process to secure the processing object so that it occupies the correct position to accept construction or inspection, also known as a fixture.

Broadly speaking, any process in the process, the device used to quickly, easily and safely install the workpiece, can be called a fixture. A tool is a large tool for carpentry, ironmaking, fitters, machinery, electrical control and other handicrafts, mainly used as a tool to aid in controlling position or movement (or both). Fixtures can be divided into three types: process assembly fixtures, project test fixtures and board test fixtures.

Basic Requirements For Good Fixtures

1, to ensure the processing accuracy of the workpiece to ensure the key, first of all, the correct selection of positioning benchmark, positioning method and positioning elements, if necessary, but also need to carry out positioning error analysis, but also pay attention to the structure of other parts of the fixture on the impact of processing accuracy, to ensure that the fixture can meet the processing accuracy requirements of the workpiece.

2, improve the complexity of production efficiency special fixtures should be adapted to the production capacity situation, should try to use a variety of fast and efficient clamping mechanism, to ensure easy operation, shorten the auxiliary time, improve production efficiency.

3, the structure of good process performance special fixtures should strive to be simple, reasonable, easy to manufacture, assembly, adjustment, inspection, maintenance and so on.

Basic Requirements For Good Jigs

4, the use of good performance of work-packing fixtures should have sufficient strength and stiffness, operation should be simple, labor-saving, safe and reliable. Under the premise that objective conditions permit and are economically applicable, as far as possible, pneumatic, hydraulic and other mechanized clamping devices should be used to reduce the labor intensity of the operator. The work-packing fixture should also be convenient for the removal of chips.

If necessary, the chip removal structure can be set up to prevent chip damage to the positioning of the workpiece and damage the tool, to prevent the accumulation of chips to bring a large amount of heat and cause the process system deformation.

5, good economy special fixture should be used as far as possible standard components and standard structure, and strive to simple structure, easy to manufacture, in order to reduce the cost of fixture manufacturing. Therefore, the design should be based on the order and production capacity of the fixture program to carry out the necessary technical and economic analysis, in order to improve the economic efficiency of the fixture in production.

Functional Classification of Jigs and Fixtures:

01 Clamp

02 Drilling, milling machine

03 CNC, instrument chuck

04 Test gas, waterwork

05 Cut edge, punching work

06 Welding

07 Polishing fixtures

08 Assembly 09 Shift printing, laser engraving