Injection Mold

Precision injection molds are used by precision machining methods to mass produce some complex shapeparts or products.

Specifically, the melted material is injected into the mold cavity at high pressure and, after cooling and curing, a variety of forming products are obtained. Precision plastic molds mainly include die combination substrate, die assembly and die combination. The die of the splint forming the variable cavity is the convex mold formed by the convex module, the convex module, the convex module, the shape cavity cutting assembly and the side cutting combination plate to form the variable core. Abrasive convex, cavity and harmonious transformation of the forming system software. Can be produced and processed different appearance, different specifications of the series of plastic parts.

Injection Mold

Product introduction: injection mold is to high efficiency, precision, long life, large-scale direction of development.Car cover parts mold development direction is medium and high-end car large and medium-sized coverage parts mold, especially the outer cover parts mold.

Processing technology: Foxdotec mold industry chain is the key component of high-tech industry, we enhance the mold architecture design concept and the type of CAD/CAE/CAM, so that it tends to intelligent system. Improve the molding process and standard level of the mold, improve the manufacturing accuracy and quality of the mold, reduce the grinding and polishing operation of the molded part surface and manufacturing cycle.Improve mold performance through research and application of high performance.

Scenarios: Automotive/Aeronautical/Marine Electronic Components, Micro Motors, Medical Devices, Precision Connectors, Medical Electronics, Smart Appliances, etc.

Mold Making

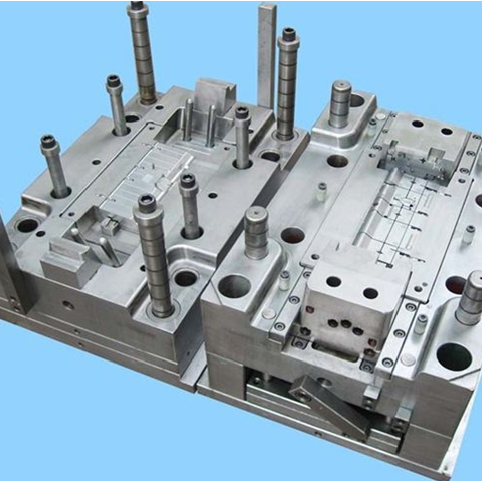

Processing process: injection mold by the dynamic mold and fixed mold composition, dynamic mold installed on the injection molding machine moving template, fixed mold installed on the fixed template of the injection molding machine. Injection molding, the active mold and fixed mold closed, forming a pouring system and cavity, open mold, active mold and fixed mold separation, take out plastic products.

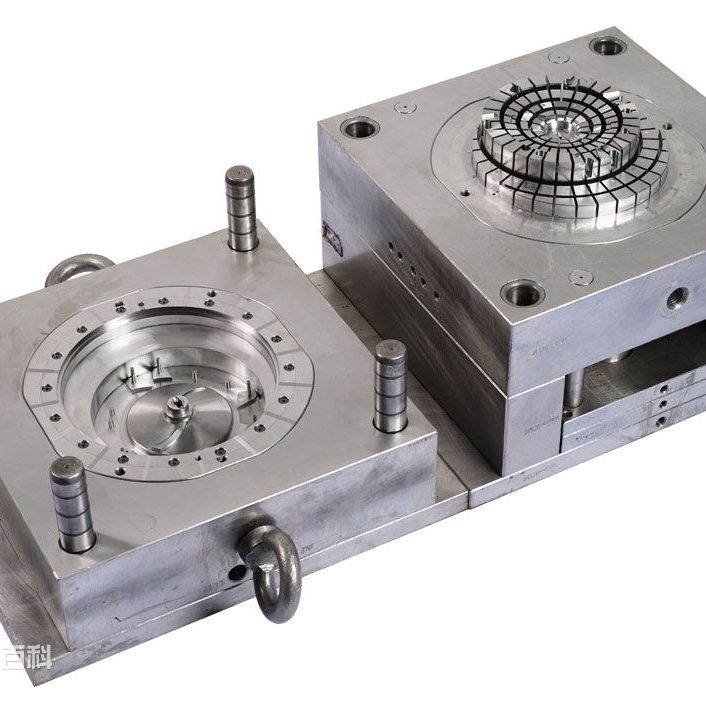

Factory advantages: FudongYu in the process of injection molding mold on the surface quality requirements are high we use ultra-fine grinding method, the technology can reach Ra0.008 m surface roughness, is the highest of all grinding methods. This method is often used in optical lens molds.

Application scene: injection mold is the production of a variety of industrial products of important process equipment. Plastics industry and plastic products in aviation, aerospace, electronics, machinery, ships and automobiles, home appliances, electronic communications, daily necessities and other industries.