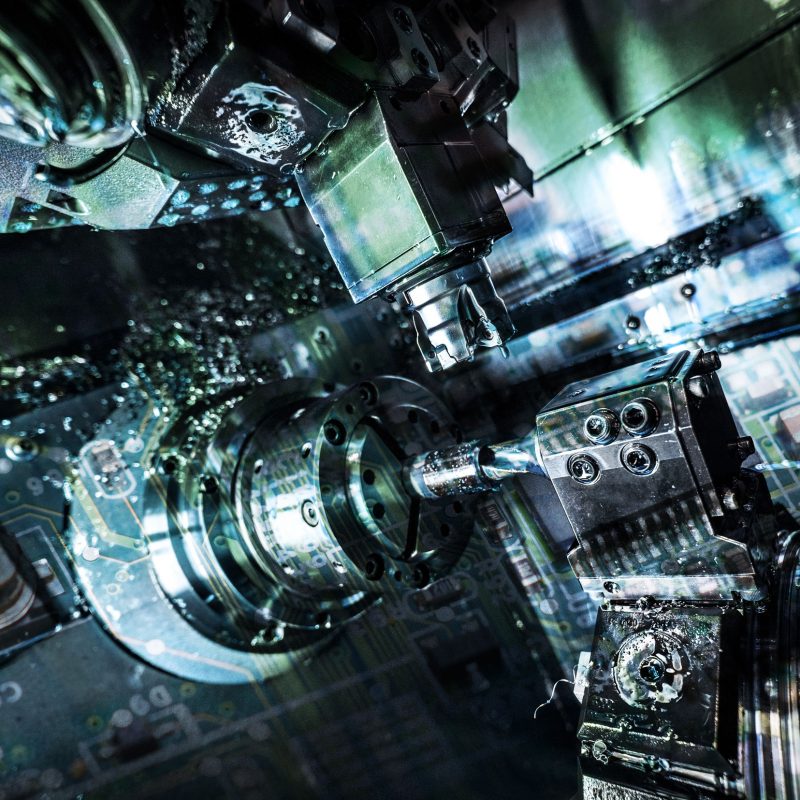

Precision Machining

Precision machining, with the premise of not changing the physical properties of the workpiece material, in order to obtain extreme shape accuracy, dimensional accuracy, surface roughness, surface integrity (no or minimal surface damage, including microcracks and other defects, residual stress, tissue changes) as the goal. Various factors affecting the precision machining accuracy include: precision machining mechanism, processed materials, precision processing equipment, precision processing tools, precision machining fixtures, precision machining detection and error compensation, precision processing environment (including constant temperature, vibration, clean control, etc.) and precision processing technology.

Precision processing technology is the key, precision and ultra-precision processing technology is one of the important indicators to measure the level of advanced manufacturing technology

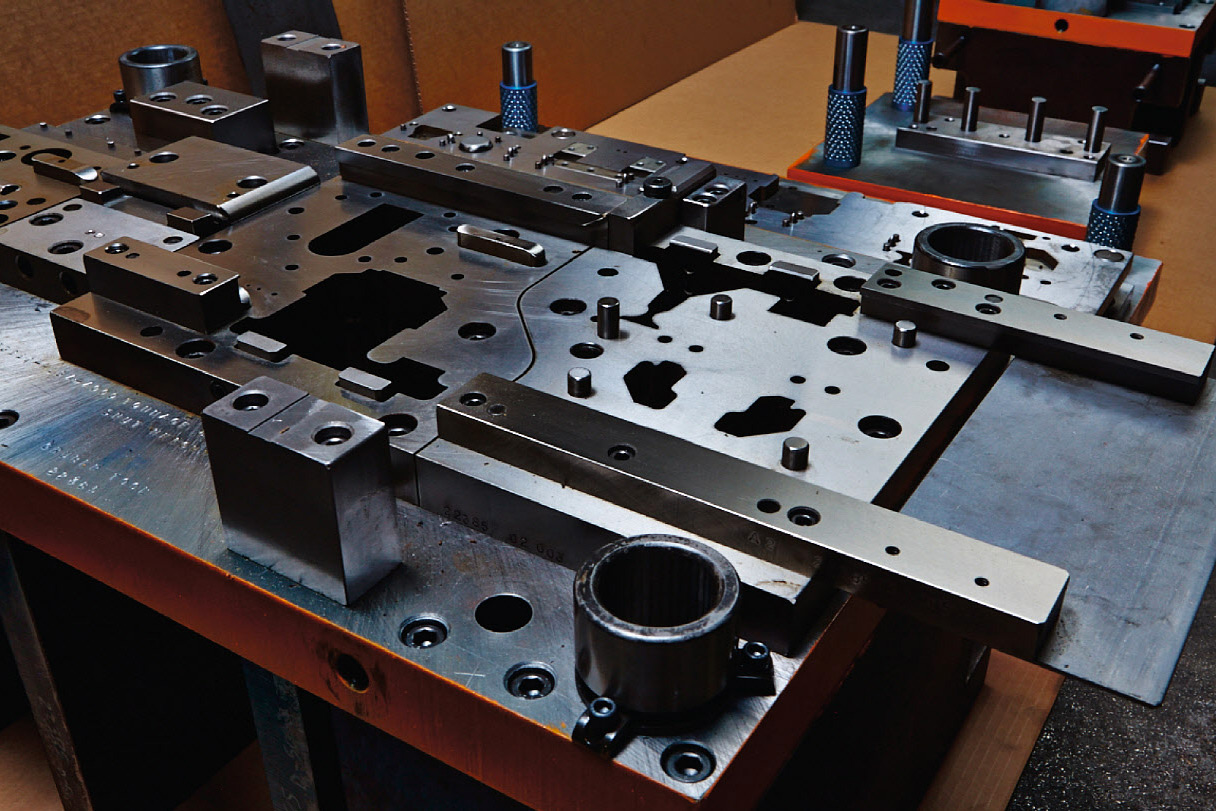

Precision Manufacturing

Precision Manufacturing is a collaborative movement process with a dense expertise, and in order to better support precision mold design and processing processes, Foxdotec has been conducting research and exploring for mold design and precision manufacturing, where data management and application is the key performance of intelligence. The company’s information construction precipitated data, through data extraction, exploration and other technologies into guide the company’s design concept processing expertise, and through the management system to penetrate into the mold precision manufacturing of all links, is a very critical future development direction.

Through the study of mold design and machining process, it is obtained that the design idea similar to the implementation of the scheme search, tool path optimization, customer order delivery estimate, load control and other related structural characteristics and related product development techniques, from CAD / CAM / PDM / ERP / MES and other information systems to extract update cases / models, Standard and other design ideas processing system data, and through these information systems directly call edgy to provide customers with services, forming a service closed-loop system for mold design and processing to provide effective precision manufacturing services

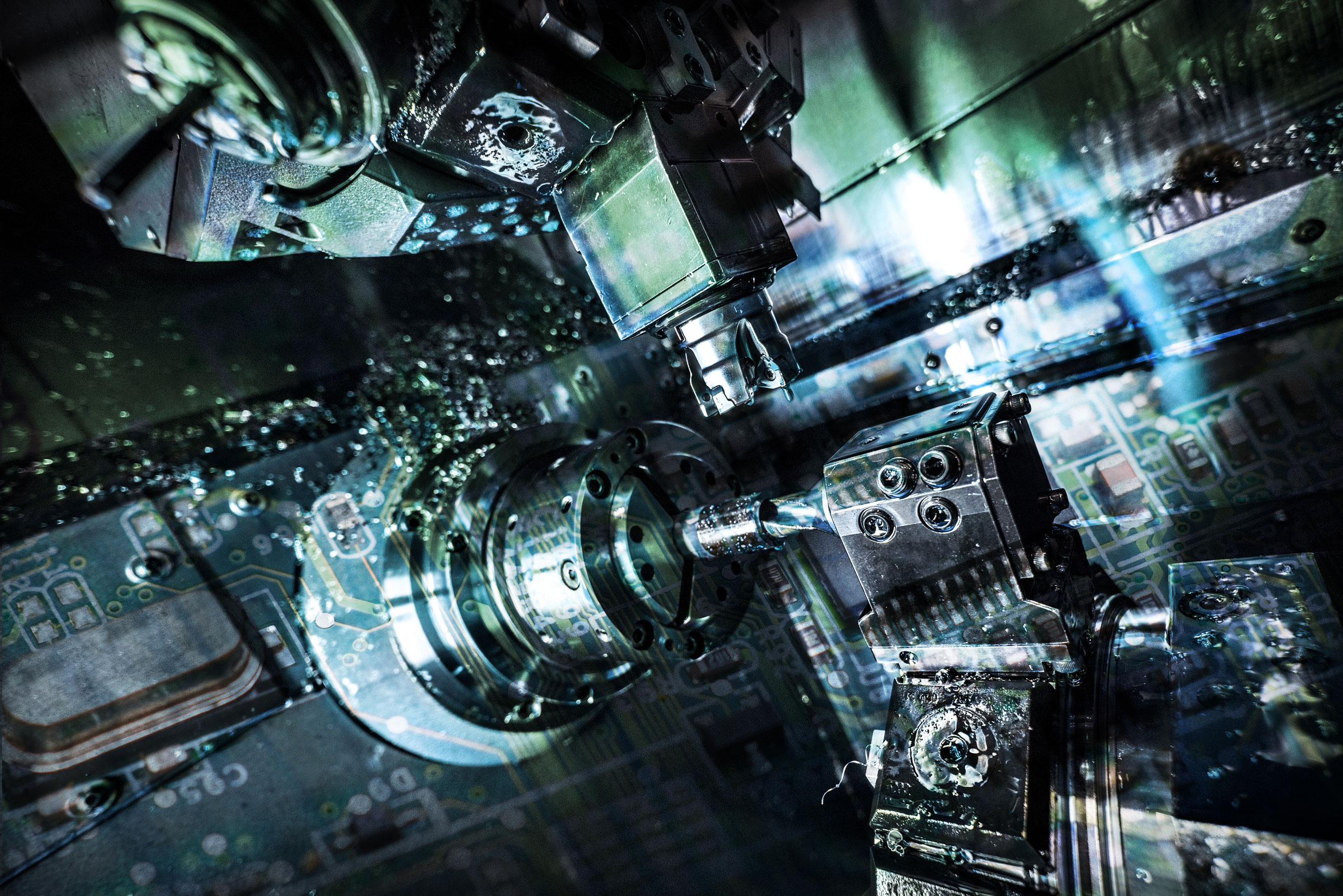

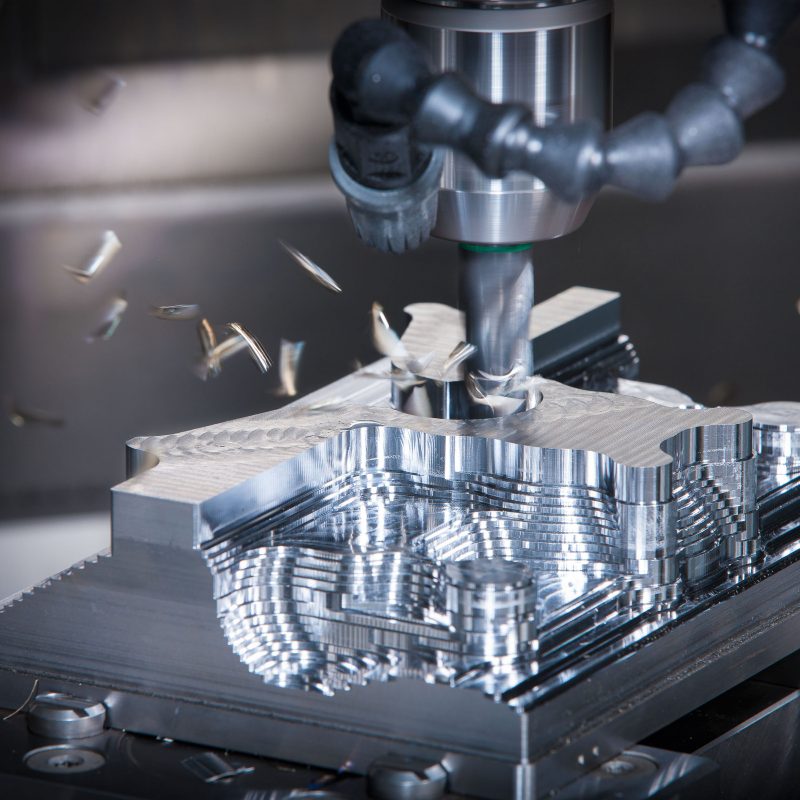

Precision Machining

Automated design: Automated design uses computer-aided design and optimization design technology to automate and optimize the design process, cnc machine tools and processing centers, robots, micro-electromechanical systems, etc., and computer control technology makes the mechanical manufacturing process automatic and intelligent, sensing technology, computer technology and mechanical design and manufacturing combinationThe close combination of machine design and operation process can realize comprehensive automation control of the design process, manufacturing process, installation and operation process of mechanical and electrical products.

Full service: Precision processing technology is an important support technology of modern high-tech equipment, and the required test instruments and equipment snare almost none of them do not need the support of precision processing technology. Foxdotec precision processing has entered the nanoscale, integrating automated research and development, design, manufacturing, assembly and commissioning and technical services as a whole, and strive to provide high-reliability, high efficiency, low-cost automation production equipment for customer needs.

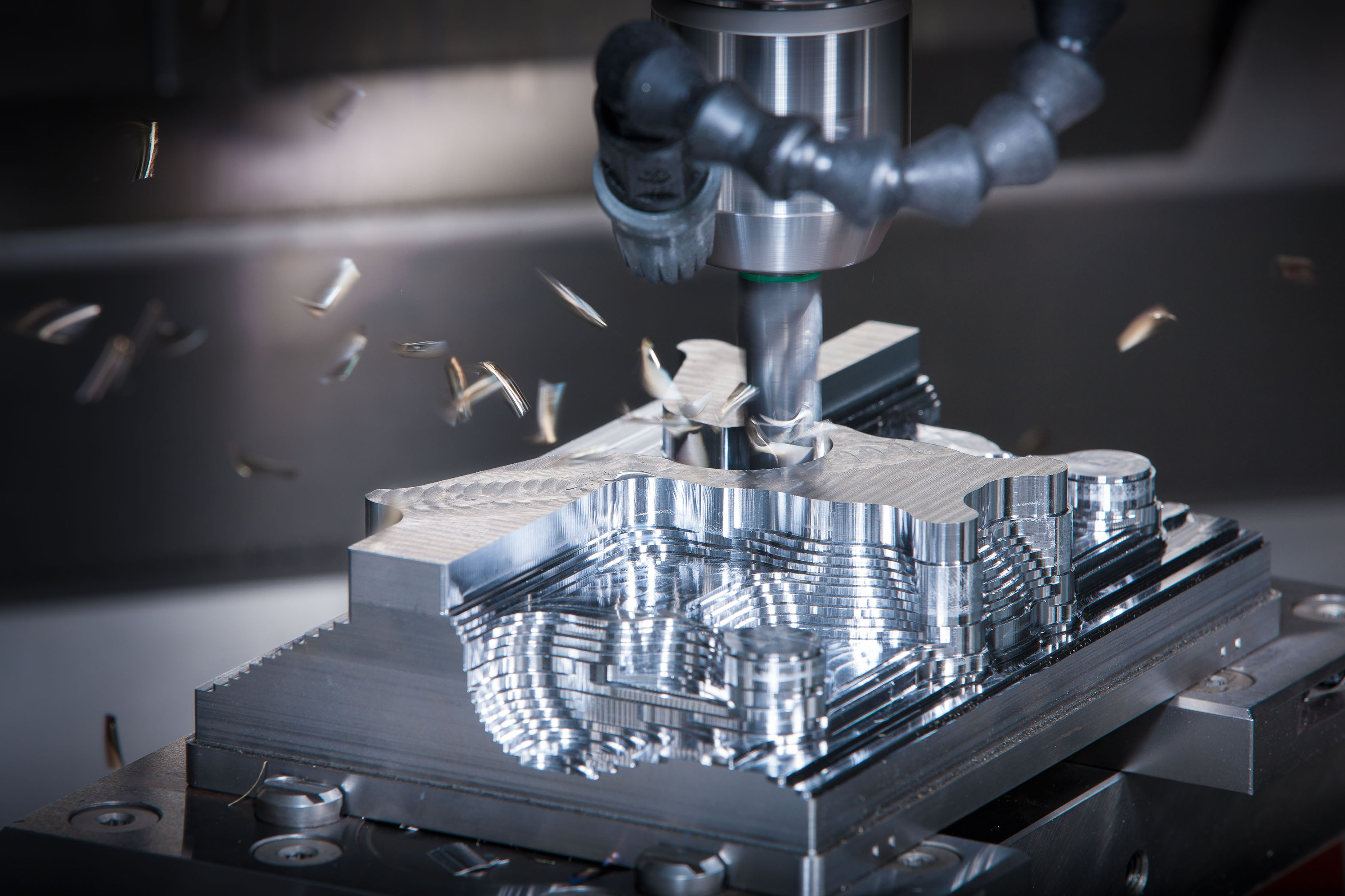

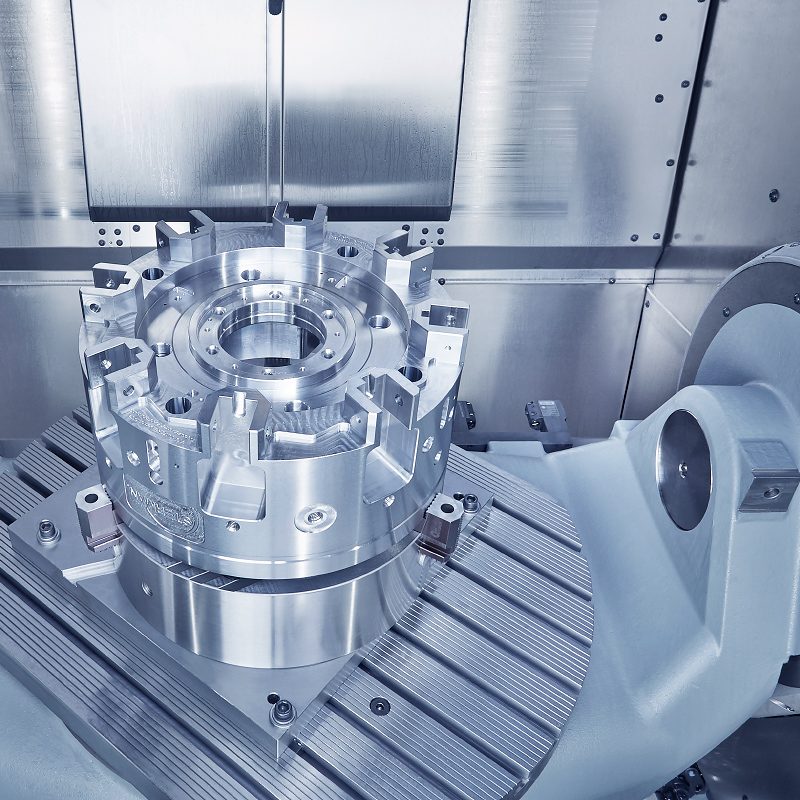

Precision parts processing

Processing: In the complex precision components, processing is very strict, processing process incision and other dimensional accuracy requirements.For example, the size of 1mm plus or minus microns and other faulty, may become waste.

(1) In order to ensure precision of precision parts processing, coarse, refined mechanical parts and components should be separated to carry out.

(2) Reasonable choice of equipment. Roughing should be done on high-power, low-precision machines.The finishing process requires high-precision machine tools.

(3) In the precision parts processing process, arrange the heat treatment process.In order to improve the cutting performance of metal, the heat treatment process annealing, positive fire, and conditioning are generally carried out before the machining of mechanical components.

Our strengths: FOXDOTEC is committed to the automotive, communications, medical and other high-end industries to provide precision parts and the world’s top 500 to establish a good relationship of cooperation, to provide precision components, consumer connectors, precision optical components, precision acoustic components of the processing services. and non-standard automation and its component design and manufacturing solutions.

ODM original design and manufacturing scheme

What is ODM: (Original Design Manufacturing) It provides users with the entire business from product development, manufacturing to future maintenance, and users simply make clear to ODM service providers the usefulness, function, and even the idea of simply providing goods. ODM service providers are able to turn goods from vision to reality. Some manufacturers, after the product, will be looked at by other companies, asked to add the company’s own brand trademarks to produce processing, market ingress, or make some small changes on the machine for production and processing, and in their own brand to market. The biggest advantage of this is that the latter reduces its product development time.The former is customary to be the ODM of the latter.

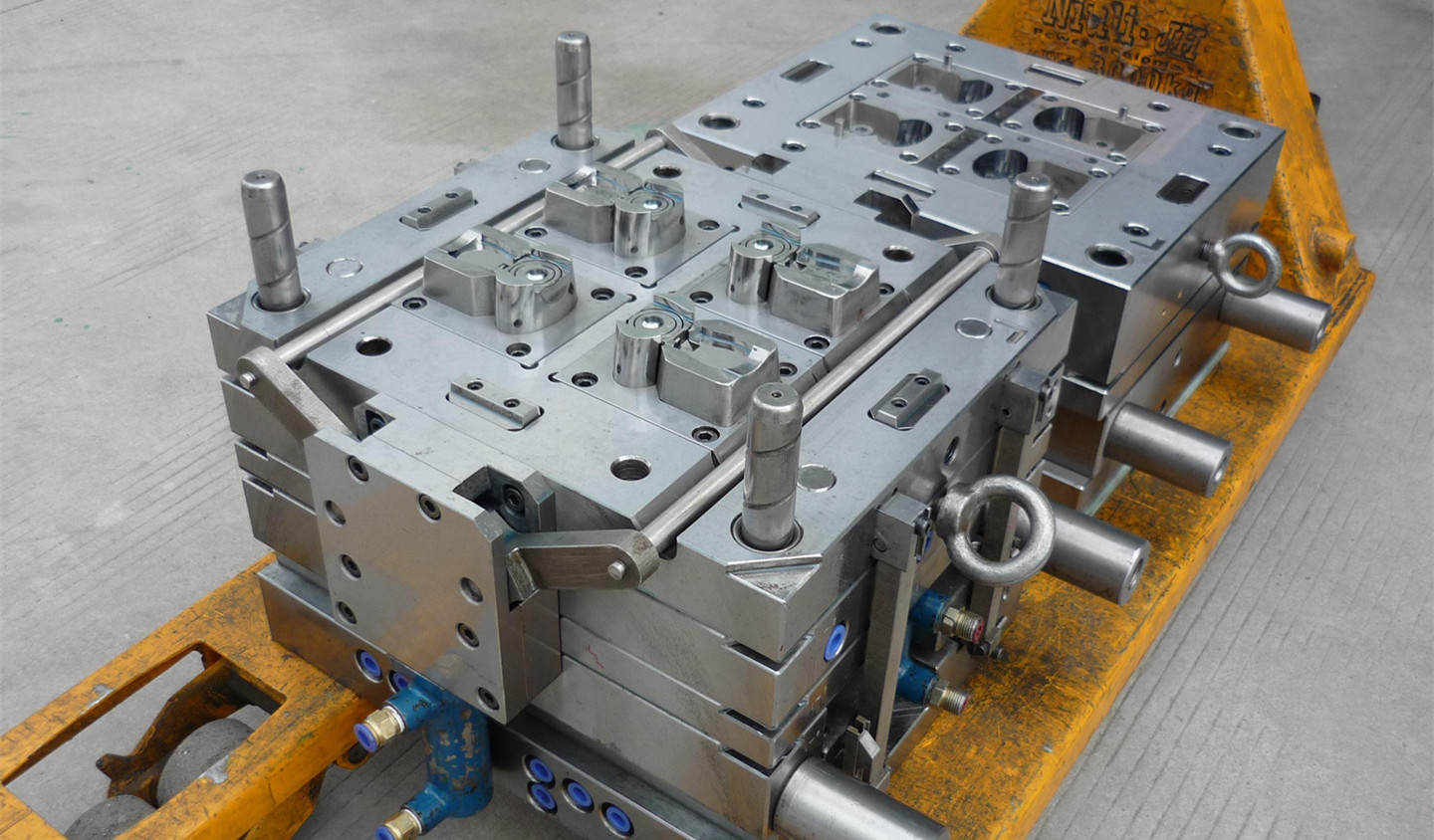

ODM benefits: Fudong has a complete industrial chain cluster. Preempted the commanding heights of “programme design”.Precision mold function and structure is becoming more complex, indicators are more demanding, ODM will be the design link under the package, the use of advantages in the field to provide customers with a variety of ready-made solutions, to minimize the development time of customer products, control into this, improve the quality and performance of products.

Solid customers: Diversified series of products and mold development and production capabilities, Fudong Yu has more than 100 traders and manufacturers of customer base as a back-up to a stable quality and accurate delivery, access to long-term customer trust and support, but also enable us to maintain survival and development in a highly competitive environment.

OEM LABEL PRODUCTION SOLUTIONS

What is an OEM: Originition equipment manufactuce (OEM). Driven by social division of labor and professional interests, its basic significance is to carry out product development and manufacturing under the original unit (brand unit) contract, using the original unit trademark, and the cooperative operation and production mode sold or operated by the original unit. OEM can be referred to simply as “processing” or “label production”.In order to increase the allocation of all resources in the innovation ability of enterprises, to minimize investment in fixed assets, enterprises do not directly produce, but let other enterprises agent production to complete the production tasks of products.

OEM benefits: Foxdotec has to meet thousands of normal product processing mold manufacturing solutions, complete and diverse choices and stable continuous supply, to meet the needs of customers of various substitute processing OEM.Also this advantage is to let our management costs are low, there is a low-cost advantage.

Equipment benefits: Japan CNC high-precision CNC machine tools, SODICK electric spark discharge processing / line cutting and discharge processing, Japan import plane / curve / internal and external round grinder, precision five-axis high-speed milling, ZEISS whole-system three-coordinate equipment, to ensure the stability of mold quality and continuous analysis and improvement, so that product quality is more perfect.