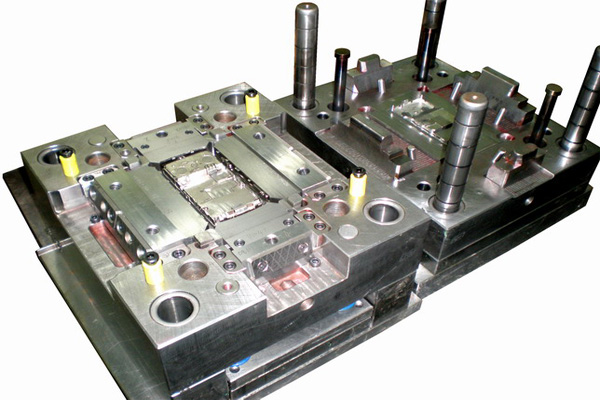

Stamping Die

Stamping molds are special technical equipment (metal or non-metallic) for processing materials (metal or non-metallic) by cold press processing to components (or semi-products), known as cold-pressed molds (commonly known as cold molds).

A press machine is a pressure-processing method for obtaining the required parts by applying pressure to the material with a mold mounted on a press machine at room temperature, causing separation and plastic deformation.

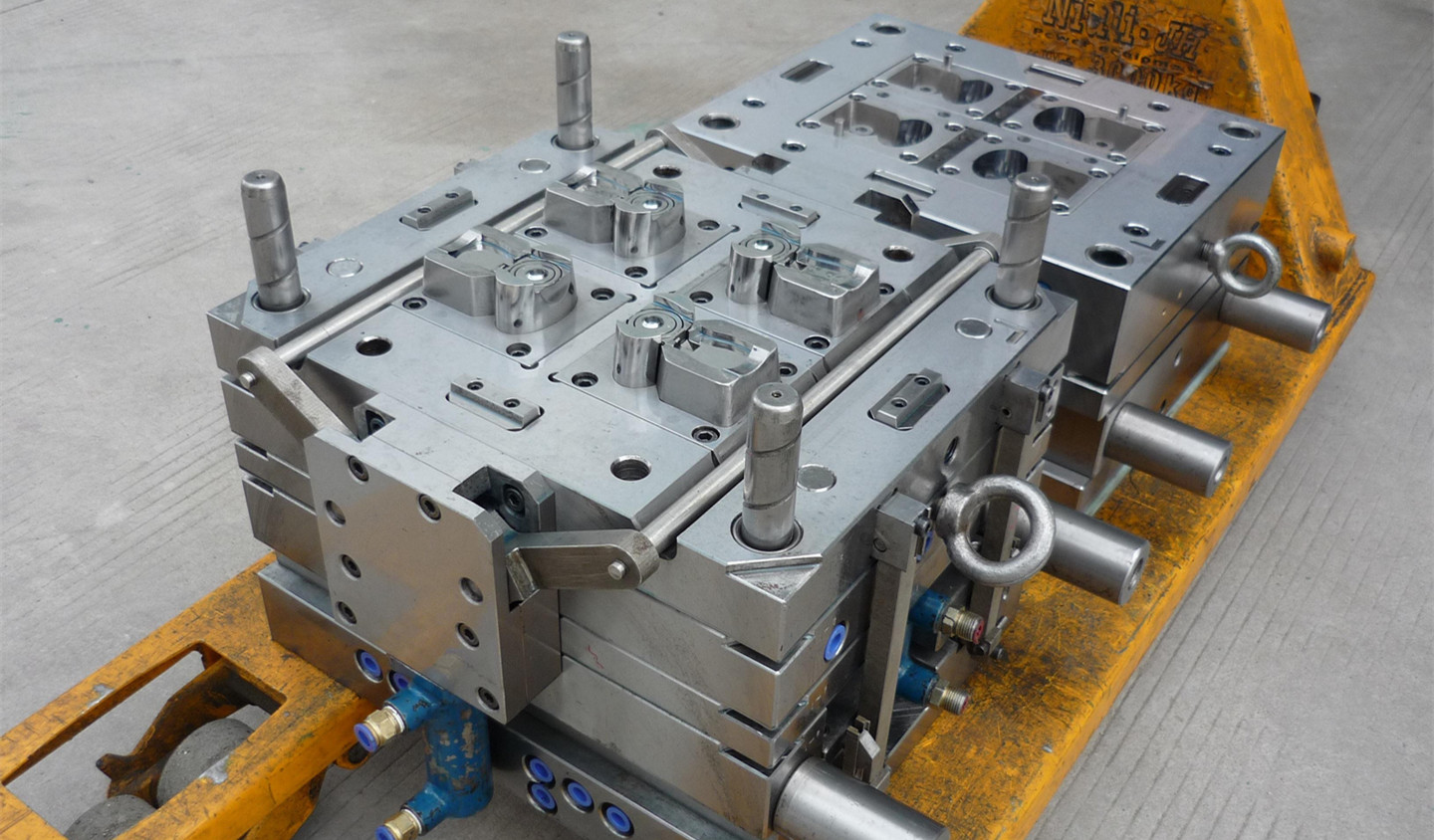

The development of advanced manufacturing technology of Fudong-yuan precision stamping mold is mainly reflected:

- High-speed milling (spindle speed is generally 15000r/min to 40000r/min, milling hardness up to 60HRC)

- Spark milling (equipped with electrode loss automatic compensation system, CAD/CAM integration system, on-line automatic measurement system and dynamic simulation system)

- Slow-walk wire cutting technology maximum cutting (speed has reached 300mm2/min, processing accuracy of up to 1.5 m)

- Grinding and polishing processing technology (with CNC forming grinders, CNC optical curve grinders, CNC continuous trajectory coordinate grinders and automatic polishing Machineadvanced equipment and technology)

- Numericalmeasurement (three-coordinate CNC measuring machine, in addition to high-precision measurement of complex surface data, but also has good temperature compensation device and reliable vibration protection)

Stamping mold should be multi-station grade intake, carbide block-level intake mold can improve the service life. In the small batch production and trial production of new products, simple molds with simple structure, fast manufacturing speed and low cost should be adopted, such as combination mold, sheet mold, polyurethane rubber mold, low melting point alloy mold, zinc alloy mold, superplastic alloy mold, etc. Molds have begun to use computer-aided design (CAD), which has been optimized through a series of computer-centric systems. This is the development direction of mold design.

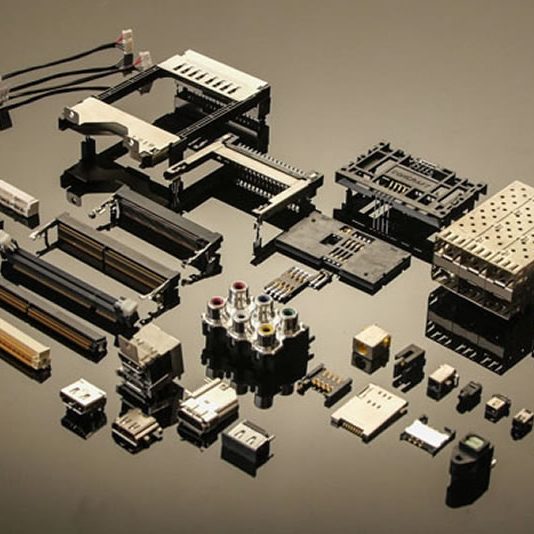

Precision Stamping Molds - Connectors

Plug-in mold introduction: precision plug-in refers to electrical and electronic equipment inside the connector and card slot. Because they are small (some only 0.25MM in diameter) and in large quantities. Therefore, the mold quality and accuracy requirements are very high.Molds similar to plugs and card slot products We call precision plug-in molds.

Product advantages: Fudong Yu in the precision plug-in mold, large, complex continuous type, multi-station robot automatic type, semi-automatic type with deep technical precipitation, can provide customers with excellent efficient and safe mold production program

Scenario: Car motorcycles, electrical appliances, IT products, office automation equipment, light industrial products, medical equipment and other manufacturing industries, as well as aircraft, ships and high-speed train equipment structure and interior parts manufacturing.

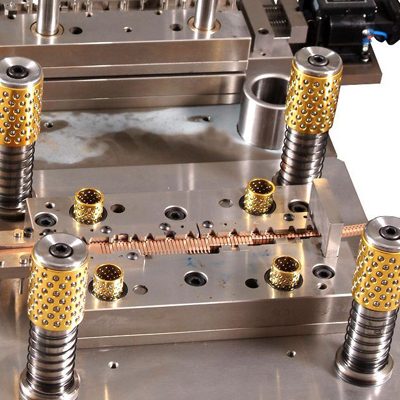

Precision Stamping Mold - Shrapnel Mold

Product introduction: in the circuit is blocked or isolated between the circuit, set up a bridge of communication, so that the current flow, so that the circuit to achieve predetermined functions.

The form and structure of the plug-in are ever-changing.

Product advantages: FudongYi professional design and manufacture of precision stamping molds and precision hardware stamping ODM / OEM professional mold manufacturers, precision shrapnel stamping molds in the manufacture of forging cutting, processing and heat treatment and other processes, to ensure the quality of precision shrapnel, reduce production costs, with good forging, machining and grinding materials Application range: mobile phone card class, mobile phone antenna, headphone audio socket, plug-in, micro-motor, sensor, car instrument touch switch, medical equipment, PCB panel shield and so on.

Precision Stamping Mold - Terminal Mold

Product Description: The terminal is a component of the battery connected to an external conductor.Electrical engineering also called terminalterminals, types of single-hole, double-hole, socket, hooks, etc. , on the degree of mold precision, high-speed terminal mold here should be considered the most sophisticated.

Product technology: mold design, mold processing, mold formation, test mold and repair of the three indispensable.A set of high-precision molds to have a precise design, precision processing, but also have precision assembly.

Applications: Precision connector terminals, medical terminals, automotive terminal mobile computer equipment, digital cameras, automotive/aeronautical/navigational electronic components, medical electronics, smart home appliances, ICs, 3C products, etc.