Mold is a precision tool, its structural strength, stiffness, surface hardness, surface roughness and processing accuracy have higher requirements, precision mold industry development level is a country’s manufacturing industry development degree of one of the important signs. China’s precision mold industry in the traditional market steady progress, but also actively explore rail transit, medical equipment, new energy, aerospace and other high-tech industries, including emerging industries. Driven by the continuous expansion of the application field, the concept of intelligent development of the mold industry began to gradually penetrate.

Precision mold enterprise production mode from discrete to centralized, from customization to scale has undergone great changes, synergy, precision, efficiency, has become leading the industrial transformation and upgrading of equipment demand trend. Precision mold industry industry development will pay more attention to the efficiency of the quality of equipment solutions, and with the improvement of technical requirements, human costs, in the context of rapid progress in big data, cloud computing, Internet of Things, artificial intelligence and other technologies, intelligent wearables, smart home, driverless industries develop rapidly, mold personalization, diversification, automation requirements are higher, mold market gradually entered a customer-centric stage of development. Mold industry needs to adjust the concept as soon as possible, through intelligent development to improve the technical content of products, to give products unique functions to meet the increasing needs of users.

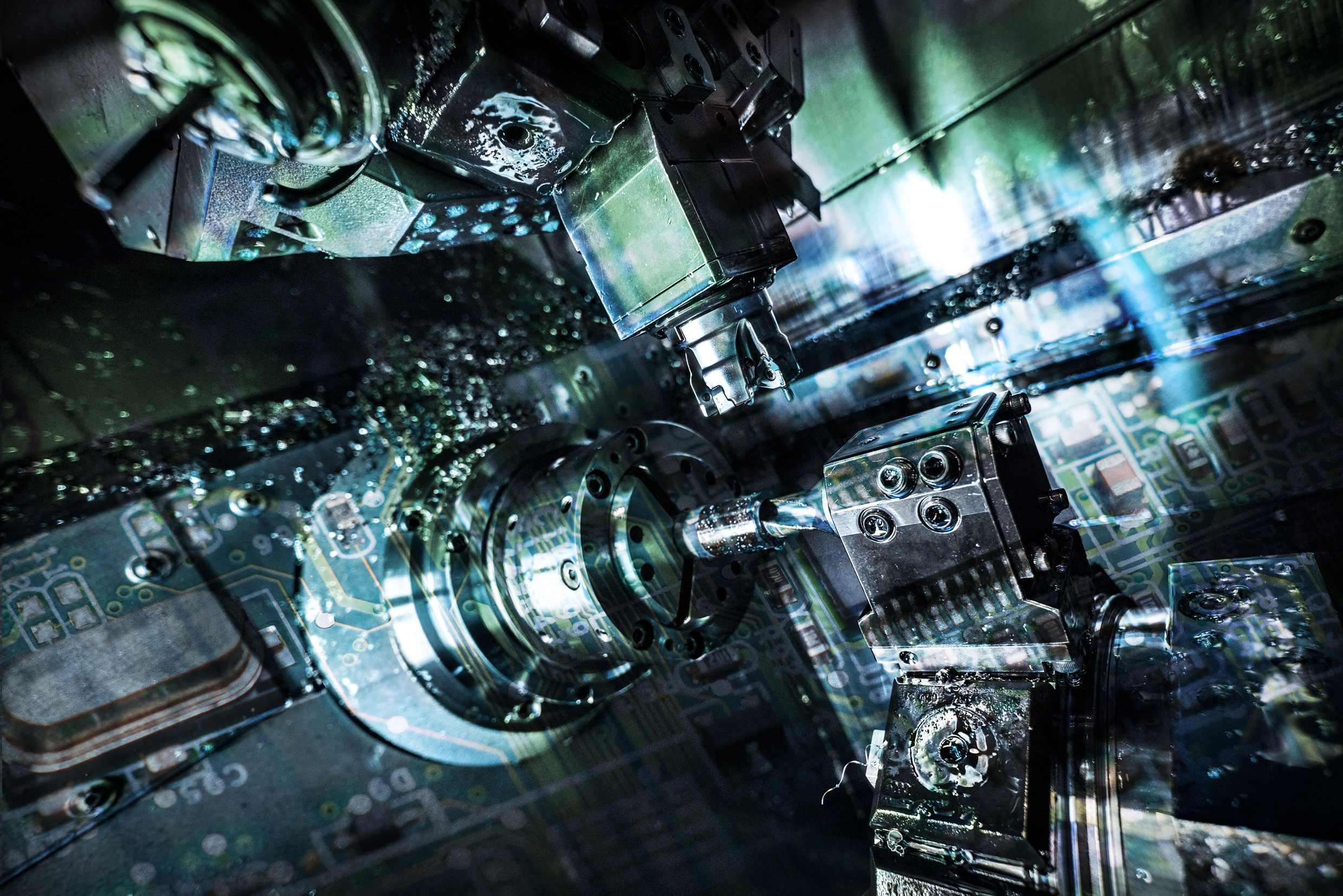

Automation, integrated technology to promote the intelligent mold manufacturing

Mold has been developed from basic process equipment to information-based, intelligent integrated manufacturing units, from a single-function process to an integrated solution. For the host plant to provide SE services and mold-based, inspection, clip integration of white body solutions has become one of the core competitiveness of mold enterprises. Modern mold industry is a capital and technology-intensive industry under the background of high technology. With the development of mold industry, modern mold to achieve digital design, digital intelligence, digital management, digital production process to achieve the modernization of the mold industry.

Information technology helps mold enterprises to realize network, integration, intelligence

Integrated software spans mold design, quality inspection and industrial management, integrating digital advanced design, manufacturing, inspection and management to provide comprehensive solutions from design, manufacturing, testing to management. For mold, tooling, non-standard and other single-piece small-volume production enterprise information technology and applications, for single-piece small-volume production enterprises to provide project management, production management, cost management, material management, automated design and programming, automated processing, CAE, PDM, NX, CATIA design and programming secondary development series of digital products and tailor-made services.

Under the strategic background of “Made in China 2025”, China’s manufacturing industry is in a critical stage of transformation and upgrading, the various industries continue to adjust the product structure to the high-end field of development, and China’s rising labor costs, in order to reduce production costs, improve production and sales rate, increase product technology content, intelligent manufacturing has become an important development trend. Mold is an indispensable key equipment in the manufacturing production process, in order to meet the downstream market demand, improve the profitability of the industry itself, intelligent mold has become the inevitable development of the industry, can not adapt to the needs of enterprises will be gradually eliminated by the market.