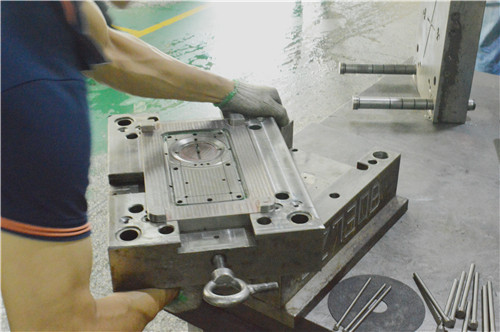

FOXDOTEC company currently has 1500 sets of size injection molds stored in the mold library, are usually often produced molds, there is a thick plastic bit, there is a thin plastic bit, there is a core pumping. And so on all kinds of injection molds. 50% of the molds are made of pc transparent material. Some product quality requirements are relatively high, to adjust the production of greater problems, but we overcome one by one, to meet customer requirements.

Today we first talk about the most difficult set of glue bit 8 mm injection mold! The prerequisites for the transfer of the machine

1. Injection machine screw is too strong

2. Glue must be raw materials do not add water mouth

3. Injection cycle should be reasonable, too fast will shine. The cycle is too slow the product will burn yellow and blacken

4. Injection molding parameters to scientific flowers

5. After molding some products need to be soaked water cooling

6. Injection mold into the glue to be perfect to achieve.